Whip Checks Safety Cable

minimizes damage to equipment and injuries

Use whip check to minimize damage to equipment and injuries to operators in the event hose, couplings or clamps fail, or there is an accidental separation of the assembly

America's # 1 Source

-

Safety Rig Whip Checks

Safety Rig is America's #1 Source for whip checks and safety cables, hose to tool service safety cable, hose to hose service safety cable and more. For more information on the whip checks we carry, email us at sales@safetyrig.com

-

Features

Our whip check are designed to provide standby safety for hose with cable reaches across hose fittings. Spring-loaded loops in the cable ends open easily to pass over the couplings for a firm grip on the hose. All easy to install and remove, no additional tools needed. All whip checks are made with highly rust and corrosion resistant materials

-

304 Steel Steel and Galvanized Carbon Steel

All whip checks are complete with 304 stainless steel or galvanized carbon steel wire rope and springs. Whip checks ferrules are made of copper or aluminum materials.

Why whip checks

minimize injuries or accidents resulting from hose or coupling failure

Whip checks are designed to help minimize injuries or accidents resulting from hose or coupling failure. A whip check extends across the hose fittings to give standby safety for a hose. Simply pull back the spring and slip the loops on the whip check over each hose before connection to provide security against hose whip. Contact us today, let us know your requirements and we will find the right whip checks for your needs.

WHIP CHECKS HOW TO

Whip checks help minimize injuries or accidents resulting from hose or coupling failure.

A whip check extends across the hose fittings to give

standby safety for hose. Simply pull back the spring and slip the loops on the whip check over each hose before connection to provide security against hose whip.

- must be installed in the extended position (no slack)

- maximum operating pressure: 200 PSI

- cable reaches across hose fittings to provide standby safety for hose

- spring-loaded loops in the cable ends open easily to pass over the couplings for a firm grip on the hose

- no tools needed, easy to install and remove

- cable shipped with safety restraint labels attached

- high resistant to rust and corrosion

- hose-to-hose or hose-to rigid outlet

- with safety clip and lanyard option

- with stainless steel safety marine eye used to connect safety cable to a bolt on tool option

- with bronze/copper ferrule for special environmental conditions option

Whip checks are designed with a 5 to 1 safety margin at 200 psi. At 300 psi that margin drops to 3 to 1. Any pressure above that is not a suitable application for whip checks and may result in injury or death in the event of an explosive coupling decompression.

We recommend whip checks be used only on AIR HOSES carrying no more than 200 PSI. Any other use is at your own risk.

If your hose application is hydraulic OR exceeds 200 psi, we strongly recommend that you use our high pressure hose safety whip restraint checks, specifically designed to prevent hose whip on high-pressure hose applications. For more information on hydraulic whip checks and high-pressure hose safety restraints EMAIL

sales@safetyrig.com or call 832-474-4440

|

|

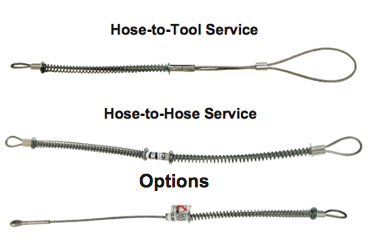

Hose-To-Hose Service Whip checksWhipcheck designed specifically to secure a hose-to-hose connection. |

|||||||||||||||||||||||||

|

||||||||||||||||||||||||||

| | ||||||||||||||||||||||||||

|

|

Hose-To-Tool Whip checksWhip check designed specifically to secure a hose-to-tool connection. |

|||||||||||||||||||||||||

|

||||||||||||||||||||||||||

| | ||||||||||||||||||||||||||

|

|

Bronze/Copper Ferrule WhipchecksWCH2 made with bronze/copper ferrules for special environmental conditions.Cable size: 1/4", Part #: WCH2B |

|||||||||||||||||||||||||

| | ||||||||||||||||||||||||||

|

|

304 SS Cable WhipchecksWCH1 or WCH2 made with 304 stainless steel cable and springs with bronze/copper ferrules for special environmental conditions.Cable size: 1/8", Part #: WCH1SS Cable size: 1/4", Part #: WCH2SS |

|||||||||||||||||||||||||

| | ||||||||||||||||||||||||||

|

|

Bolt-On WhipchecksWCHT1 made with stainless steel safety marine eye used to connect safety cable to a bolt on tool.Cable size: 1/8", Part #: WCHT1E |

|||||||||||||||||||||||||

| | ||||||||||||||||||||||||||

|

|

Hose-To-Hose Lanyard WhipchecksWCH1 made with safety clips and lanyards used to lock Air King, A type, Surelock Couplings.Cable size: 1/8", Part #: WCH1C |

|||||||||||||||||||||||||

| | ||||||||||||||||||||||||||

|

|

Hose-To-Tool Lanyard Whip checksWCHT1 made with safety clips and lanyards used to lock Air King, A type, Surelock Couplings.Cable size: 1/8", Part #: WCHT1C |

|||||||||||||||||||||||||

� Whip check is the low cost answer to eliminate injuries caused by broken air hose connections

� Whip checks use strong steel cables to help prevent hose whip.

� Highly resistant to rust and corrosion

� Hose-to-hose or hose-to-rigid outlet

� No tools needed - Easy to install and remove

� Upon request, whip checks are also available with bronze/copper ferrules.

� Also available with 304 stainless steel cable and springs with bronze/copper ferrules.

� Accepted by: OSHA, MSHA, U.S. Army Corps. of Engineering, Bureau of Mines, Bureau of Reclamation

INSTALLATION !!!

|

|

|

|

Incorrect Install Whip checks should NOT be installed with slack in the safety cable. |

Correct Install Whip checks should be installed in the FULLY EXTENDED position. |

HYDRAULIC / HIGH-PRESSURE HOSE SAFETY

Hose whip checks and safety accessories specifically designed for use with hydraulic OR other high-pressure hose applications exceeding 200 PSI.|

|

High-Pressure WhipchecksWhip checks limit the hose from whipping in the event of a connection failure. Whip checks are made of durable nylon strapping with extra heavy stitching. |

| | |

|

|

Containment GripsContainment grips limit the possibility of serious injury to personnel in the event of a connection failure. Containment grips are available in stainless steel or galvanize plated carbon steel |

| | |

|

|

Support GripsSupport grips assist in holding the weight of the hose as it hangs in vertical or slanted positions. Support grips are made of high grade, coated, galvanized wire. |

| | |

|

|

Bend RestrictorsBend restrictors, which are available for most hoses, assist in reducing the stress near the end fitting as well as prevent kinking of the hose. Bend restrictors are made of PVC material. |

| | |

|

|

Spring GuardsSpring guards, which are available for most hoses, reduce stress near the hose end fitting and prevent kinking of the hose. In addition, they can be custom fit to the length of the hose. Spring guards are made of high tensile spring steel with a rust resistant coating. |

| | |

|

|

Burst GuardsBurst guards protect the operator and surrounding equipment from hose failure. Burst guards are made of synthetic rubber with wire steel reinforcement. |

| | |

|

|

Abrasion CoversAbrasion covers help protect the hose from excessive wear due to use on rough surfaces. Abrasion covers are made of clear vinyl and reinforced with a rigid PVC helix coil. |